1964–1972 Chevelle Small Block Identification Guide

When it comes to restoring or verifying the originality of your Chevelle, correctly identifying the small block under the hood an important step. After all,

If you’re staying true to old school with a Small-Block or Big-Block engine under the hood, setting and maintaining the correct ignition timing is crucial. Without the proper timing, your engine will run poorly, can overheat, and get bad mileage. Setting the timing is a simple process and something you should check every so often to make sure it’s still correct.

You’ll need a basic set of wrenches to loosen and tighten the hold-down clamp. The only special tool you’ll need is a timing light, which can be had for about $30 at Harbor Freight if you don’t already have one. Some option items are a vacuum gauge and possibly timing tape.

Prepare the Engine:

Locate Timing Marks:

Initial Timing Setting:

Connect Timing Light:

Connect Timing Light to No. 1 Spark Plug:

Start the Engine:

Aim the Timing Light:

Read the Timing Marks:

Adjust the Timing:

Tighten the Distributor Bolt:

Before you take off for a cruise, double-check the timing. Sometimes tightening down the distributor hold-down clamp can you can accidentally twist the distributor. After that reconnect the vacuum advance hose.

If you want, you can check and set the total timing. Rev the engine to around 3,000 RPM and check the timing. The total timing (initial + mechanical advance) should be within specifications.

After you’re done, go drive the car and see how it does. Sometimes you might need to advance or retard the timing of a degree or two in order to get it just right. If you have any other questions or need parts for your ignition system, hop on SS396.com or give our friendly techs a call at (203) 235-1200!

When it comes to restoring or verifying the originality of your Chevelle, correctly identifying the small block under the hood an important step. After all,

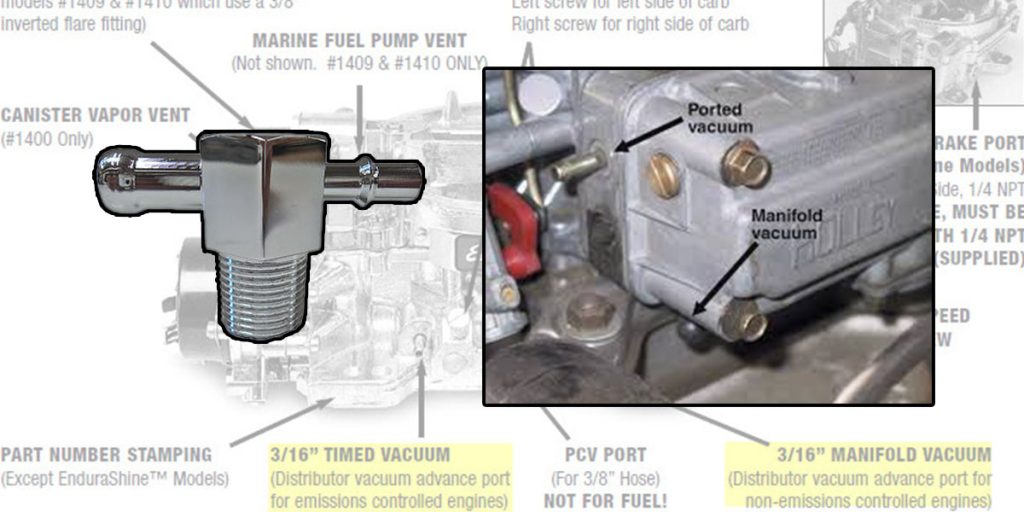

Ported vs. Manifold Vacuum for Distributor Vacuum Advance in GM Applications In the world of classic General Motors (GM) engines, proper ignition timing is needed

1964–1972 Chevelle RPO Codes: A Complete Breakdown If you’re restoring, decoding, or just plain geeking out over a 1964-1972 Chevrolet Chevelle, then you’re probably checking